close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-07-15 Origin: Site

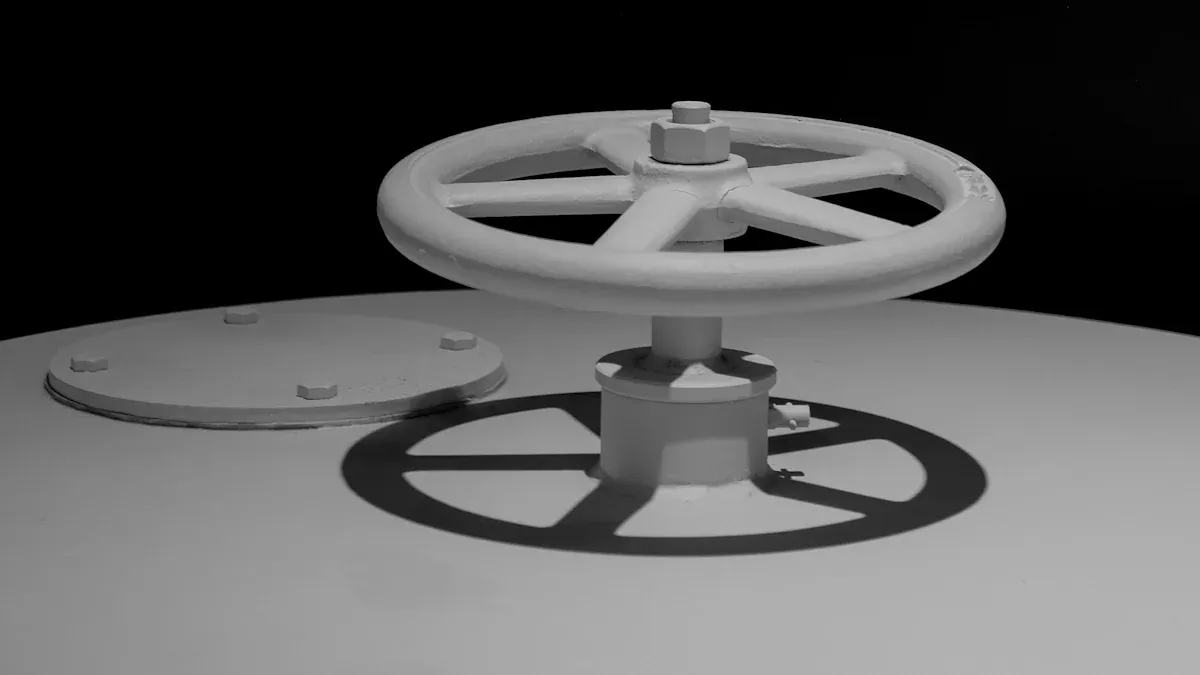

When you select a handwheel for machine tool equipment, you encounter a range of designs and materials. The most common types include spoked, solid, and arm handwheels. Spoked handwheels lead the market, as shown below:

| Handwheel Type | Market Share (%) |

|---|---|

| Spoked Handwheels | 45 |

| Solid Handwheels | 35 |

| Arm Handwheels | 20 |

You can choose from materials such as bakelite handwheel, cast iron, steel, aluminum, and plastic. For many operators, the bakelite corrugated solid hand wheel stands out because it offers a comfortable grip and reliable control. Ergonomic design matters. Studies show that the right bakelite corrugated solid hand wheel helps prevent injuries and improves performance. If you want a durable, easy-to-use solution, a bakelite corrugated solid hand wheel fits many industrial needs.

Safety Tip: Always consider handwheel diameter, rim shape, and placement. These factors affect both your comfort and operational safety.

Handwheels come in several types: fixed, revolving, folding, solid, and spoked, each suited for different machine controls and environments.

Materials like bakelite, cast iron, steel, aluminum, and plastic affect handwheel strength, durability, and resistance to heat or chemicals.

Bakelite corrugated solid handwheels offer a strong, comfortable grip and resist heat and chemicals, making them ideal for many industrial uses.

Choose handwheels based on your machine’s needs, considering size, torque, safety, ergonomics, and the working environment.

Ergonomic features like contoured grips and foldaway handles reduce operator fatigue and improve safety during long or repetitive tasks.

Regular maintenance, including cleaning, inspection, lubrication, and timely replacement, keeps handwheels safe and extends their lifespan.

Budget affects your choice; investing in quality materials and ergonomic designs pays off with better performance and longer use.

Always match handwheel specifications to your application and environment to ensure comfort, control, and reliable operation.

A fixed handwheel stays attached to its shaft and rotates as you turn it. You use this type of handwheel when you need direct, manual control over a machine part. Fixed handwheels play a key role in many industries, including manufacturing, shipbuilding, and plant construction. You often find them on valves, doors, and machine tool equipment.

The bore is the central hole in a handwheel. It lets you attach the handwheel securely to a shaft.

You can choose from several bore designs, such as hexagonal, tapered, threaded, splined, or keyway fit. Each design helps lock the handwheel in place.

Common locking methods include keyways and set screws. These methods prevent slippage and ensure reliable operation.

Fixed handwheels come in different styles. Spoked handwheels give you a simple, uniform grip. Solid disk handwheels work well in tight spaces and offer extra safety with an enclosed rim. Safety clutch handwheels help prevent accidental movements. Some fixed handwheels have retractable handles to save space and reduce accidents.

Note: Secure mounting of a fixed handwheel is important. It keeps your equipment safe and ensures smooth operation.

Foshan Grace Machinery Co., Ltd. offers a wide range of fixed handwheels. Their solid handwheels with keyways are ideal for precise adjustments on milling machines. You can also find three-spoked handwheels and round handwheels designed for durability and easy installation.

A revolving handwheel features a handle that spins freely while the wheel itself turns. This design gives you better control and comfort, especially during long or repetitive tasks. You often use revolving handwheels for fine adjustments on industrial machines, such as grinders, lathes, and CNC equipment.

Revolving handwheels allow for precise control. You can make small, accurate changes to your machine settings.

The design is user-friendly and easy to operate. You get visual confirmation of the position, such as whether a valve is open or closed.

These handwheels are durable and built for frequent use.

You need enough space around the handwheel to turn it safely. The handle's movement requires clearance.

Ergonomics matter. Proper handwheel height and angle reduce fatigue and help prevent injuries.

Studies show that using revolving handwheels can sometimes be physically demanding. Operators may need to apply high torque, which can lead to fatigue or injury if the handwheel is not positioned correctly. Choosing the right size and design helps prevent these problems.

Foshan Grace Machinery Co., Ltd. produces revolving handwheels with ergonomic handles. Their products support micro-adjustments and offer real-time feedback, making them suitable for tasks that require accuracy and comfort.

A folding handwheel has a handle that you can fold away when not in use. This feature saves space and helps prevent accidental bumps or injuries. You often see folding handwheels on equipment where space is limited or where safety is a concern.

The folding handle design lets you store the handwheel close to the machine body.

You can quickly unfold the handle when you need to make adjustments.

Folding handwheels are ideal for applications where you want to avoid protruding parts.

They help reduce the risk of snagging or accidental movement in busy work areas.

Foshan Grace Machinery Co., Ltd. offers folding handwheels that combine safety and convenience. Their products use high-quality materials and precise engineering to ensure smooth operation and long-lasting performance.

A solid handwheel, sometimes called a disk or flat handwheel, features a closed rim and a solid disk structure. You often choose this type when safety is a top priority. The closed design blocks access to the shaft, which helps prevent accidental contact and injuries. Solid handwheels work well in environments where you want to avoid pinch points or where you need to keep moving parts covered.

You will find solid handwheels on many types of machine tool equipment. They fit best in tight spaces because the disk shape does not have open areas. This design also makes them easier to clean, as dust and debris cannot collect inside spokes. Solid handwheels usually weigh more than spoked versions, which can give you a sturdy feel during operation.

Foshan Grace Machinery Co., Ltd. offers solid handwheels with keyways. These products provide precise control for milling machines and other industrial tools. You can rely on their solid handwheels for durability and smooth performance.

Here is a comparison between solid and spoked handwheels:

| Feature | Solid (Disk or Flat) Handwheels | Spoked Handwheels |

|---|---|---|

| Structure | Closed rim, solid disk | Open design with typically 2 to 3 spokes |

| Weight | Heavier | Lighter |

| Safety | Prevents axial access, reducing injury risk | May present pinch points due to open spokes |

| Size Suitability | Less ideal for large wheels | Suitable for larger sizes |

| Torque Handling | Generally lower torque capacity | Can handle high-torque requirements |

| Application Consideration | Enhances safety, used where axial access must be blocked | Allows axial access, preferred where this is needed |

Tip: Choose a solid handwheel if you need extra safety or if your workspace has limited room.

A spoked handwheel uses an open design with two or three spokes connecting the rim to the center hub. This structure makes the handwheel lighter and easier to turn, especially when you need to handle high torque. You often see spoked handwheels on larger machines because the open design supports bigger diameters without adding too much weight.

You will find spoked handwheels in many manufacturing environments. They give you a strong grip and allow for precise manual adjustments. Here are some common uses:

You can use spoked handwheels for fine adjustments in glass manufacturing machinery.

In glass blowing machines, you control the movement and angle of the blowpipe to shape glass objects.

In glass cutting machines, you adjust the height and pressure of cutting blades for clean, accurate cuts.

In glass annealing furnaces, you regulate temperature and airflow for proper cooling and strengthening.

Spoked handwheels provide reliable manual backup if electronic controls fail.

The open design makes them easy to maintain. You only need simple cleaning and lubrication.

Foshan Grace Machinery Co., Ltd. produces three-spoked handwheels made from durable materials like cast iron and stainless steel. These handwheels withstand harsh environments and deliver consistent performance. You can trust their spoked handwheels for both precision and reliability.

Note: Spoked handwheels work best when you need both strength and control for large or heavy-duty applications.

When you need a handwheel that stands up to tough environments, a bakelite handwheel is a smart choice. Bakelite is a duroplastic material known for its excellent resistance to chemicals, oils, and grease. This makes it ideal for heavy machinery, CNC equipment, and any setting where exposure to harsh substances is common.

| Feature | Description |

|---|---|

| Material | Premium Bakelite, resists solvents, oils, and grease |

| Chemical Resistance | Withstands common industrial chemicals |

| Durability | Handles wear and tear, even with frequent use |

| Temperature Resistance | Operates safely up to 150°C |

| Design | Ergonomic, often three-spoked for better grip |

| Compatibility | Fits a wide range of machines, including mills and conveyors |

| Application | Perfect for harsh industrial environments |

You will notice that a bakelite handwheel offers a comfortable grip and reliable control. The ergonomic design helps you operate machinery for long periods without discomfort. You can install these handwheels easily, and they work well in both precision machines and larger equipment. Foshan Grace Machinery Co., Ltd. uses high-quality bakelite to ensure each handwheel meets strict standards for durability and safety.

Tip: Choose a bakelite handwheel if you need a solution that resists chemicals and high temperatures.

A cast iron handwheel gives you strength and durability for demanding jobs. Cast iron is heavier than other materials, but this weight provides stability and control. You often find these handwheels on heavy machinery, presses, and machine tools where you need to make precise adjustments or apply significant force.

You can use a cast iron handwheel to manually operate valves, adjust tables, or control cutters.

In the printing industry, these handwheels help regulate roll tension and feed materials.

Large diameter cast iron handwheels are perfect when you need extra leverage.

Cast iron resists deformation, so you can rely on it for high-strength applications. Foshan Grace Machinery Co., Ltd. manufactures cast iron handwheels that meet rigorous quality standards. Their products are designed for long-lasting performance in tough industrial settings.

Note: If your work involves heavy-duty machinery, a cast iron handwheel delivers the strength you need.

Steel handwheels offer a balance between strength and weight. You get good mechanical strength and corrosion resistance, especially if you choose stainless steel. This makes steel handwheels suitable for machinery in harsh or corrosive environments, such as food processing plants or outdoor equipment.

| Material | Strength-to-Weight Characteristics | Typical Application |

|---|---|---|

| Stainless Steel | Good strength, corrosion resistant, moderate weight | Machinery in harsh or corrosive environments |

| Cast Iron | High strength, heavier weight | Heavy-duty machinery |

| Aluminum | Lightweight, lower strength | Applications needing easy maneuverability |

You will find steel handwheels in industries like mining, construction, and manufacturing. Their strength-to-weight ratio means you can use them for reliable performance without adding unnecessary bulk to your equipment. Foshan Grace Machinery Co., Ltd. produces steel handwheels that combine durability with precise engineering, ensuring they meet the demands of modern industry.

Remember: Steel handwheels are a great choice when you need both strength and resistance to corrosion.

When you need a handwheel that combines strength with light weight, aluminum stands out as an excellent choice. Aluminum handwheels offer several advantages, especially in environments where corrosion resistance is important. You often see these handwheels on equipment exposed to moisture, chemicals, or outdoor conditions.

Aluminum handwheels resist rust and weathering because aluminum does not oxidize easily.

Powder coating or chrome plating adds a protective layer, making the handwheel even more durable and easy to clean.

The lightweight nature of aluminum means you can operate machinery with less effort, which reduces fatigue during repetitive tasks.

Tip: Choose an aluminum handwheel for applications in marine, food processing, or outdoor machinery. You will benefit from its rustproof qualities and long-lasting performance.

Foshan Grace Machinery Co., Ltd. manufactures aluminum handwheels that meet strict quality standards. Their products feature precise engineering and smooth finishes, ensuring reliable operation in demanding environments. You can trust these handwheels to maintain their appearance and function, even after years of use.

Here is a quick comparison of aluminum handwheels:

| Feature | Benefit |

|---|---|

| Corrosion Resistance | Maintains durability in humid settings |

| Lightweight | Easy to handle and install |

| Protective Coatings | Enhances longevity and cleaning ease |

| Application | Ideal for outdoor and industrial use |

Plastic handwheels give you a practical solution for many light-duty applications. You often find them in smaller machines, commercial equipment, and situations where you do not need to apply much force. Plastic handwheels are popular because they are lightweight, affordable, and immune to rust.

You can use plastic handwheels in industries like food processing, medical devices, and light machinery.

These handwheels resist solvents, grease, and most chemicals, making them suitable for clean environments.

Solid technopolymer handwheels withstand high temperatures and wear, so you can rely on them for frequent adjustments.

Folding and crank handles made from thermoplastic materials are common on lathes and other machines that require quick, easy changes.

Note: Plastic handwheels are not designed for heavy-duty tasks. They work best when you need a simple, cost-effective, and corrosion-resistant option.

Foshan Grace Machinery Co., Ltd. offers plastic handwheels that combine easy installation with reliable performance. Their products use high-quality polymers to ensure smooth operation and a comfortable grip. You can select from various sizes and designs to match your specific needs.

| Feature | Benefit |

|---|---|

| Lightweight | Reduces operator fatigue |

| Chemical Resistance | Withstands solvents and grease |

| Cost-Effective | Affordable for basic applications |

| Application | Best for light-duty and quick adjustments |

The bakelite corrugated solid hand wheel stands out because of its unique design and material. You get a product that combines strength, comfort, and durability. Here are some features that make this handwheel different from others:

Made from Bakelite, a phenolic resin that resists heat and chemicals.

Corrugated surface and ergonomic handle give you a secure grip and reduce hand fatigue.

Solid cast iron structure adds strength and ensures a long service life.

Lightweight, weighing about 1 kg, so you can handle and install it easily.

Compact size (10x10x10 cm) makes storage and packaging simple.

More resistant to heat and chemicals than many plastic or metal handwheels.

Compatible with many types of machinery, such as lathes, mills, and control valves.

Some models include keyways or folding handles for extra convenience.

Tip: The corrugated design helps you keep a firm hold, even if your hands are oily or wet.

You can use the bakelite corrugated solid hand wheel in a wide range of industrial settings. Its tough construction and ergonomic design make it a popular choice for both heavy-duty and precision tasks. Here are some common applications:

Machine tools, including milling machines and lathes.

Control valves in chemical plants or food processing facilities.

Grinders and saws where you need precise manual adjustments.

Equipment that requires frequent operator input, such as presses or conveyors.

Environments where exposure to heat, oil, or chemicals is common.

The bakelite corrugated solid hand wheel fits well in places where you need both comfort and control. Its compatibility with different machines means you can use it in many industries.

When you choose a bakelite corrugated solid hand wheel, you gain several important benefits. These advantages help you work more efficiently and safely.

| Advantage | Description |

|---|---|

| Superior Durability | Bakelite and cast iron resist wear, heat, and chemicals. |

| Ergonomic Grip | Corrugated surface and handle reduce fatigue during long shifts. |

| Easy Handling | Lightweight and compact, so you can install or replace it quickly. |

| Versatile Use | Works with many machines and adapts to different tasks. |

| Customization Options | Keyways and folding handles add flexibility for your needs. |

You will notice that the bakelite corrugated solid hand wheel lasts longer than many other types. Its design keeps you comfortable, even during repetitive tasks. The advantages of bakelite handwheels include their ability to withstand harsh environments and provide reliable performance day after day.

Note: If you want a handwheel that combines safety, comfort, and durability, the bakelite corrugated solid hand wheel is a smart choice for your machinery.

You can find a wide range of sizes when you look at bakelite corrugated solid hand wheel options. The right size depends on your machine and the type of adjustment you need. Most bakelite corrugated solid hand wheel models come in diameters from 80 mm up to 250 mm. Smaller sizes work well for compact machines or fine adjustments. Larger sizes give you more leverage, which helps when you need to apply more force.

| Diameter (mm) | Typical Use Case | Weight (kg) |

|---|---|---|

| 80 | Small machines, light controls | 0.4 |

| 125 | General machinery, valves | 0.7 |

| 160 | Milling machines, lathes | 1.0 |

| 200 | Heavy-duty equipment | 1.3 |

| 250 | Large presses, industrial tools | 1.7 |

You should always match the size of the bakelite corrugated solid hand wheel to your application. This ensures you get the best control and comfort.

The handle design on a bakelite corrugated solid hand wheel makes a big difference in how you use it. Most models feature operating handwheels with ergonomic grips. These grips help you hold the bakelite corrugated solid hand wheel comfortably and work more efficiently. You will also find fixed handwheels, which attach directly to the machine and work with other moving parts.

Ergonomic grips support your hand and wrist, reducing strain.

Contoured shapes and padding fit different hand sizes.

Some handles offer adjustable settings for personal comfort.

These features make it easier to use the bakelite corrugated solid hand wheel for long periods without fatigue.

Tip: Choose a bakelite corrugated solid hand wheel with an ergonomic handle if you want to reduce discomfort during repetitive tasks.

You will find that assembling a bakelite corrugated solid hand wheel is straightforward. Each handwheel comes with all the hardware you need and clear instructions. You should follow the steps closely to ensure a secure fit and safe operation.

Use the supplied hardware and follow the instructions for installation.

Make sure the ergonomic features, such as the revolving handle, are properly engaged.

Check that all locking mechanisms work correctly to prevent accidental movement.

After assembly, clean the bakelite corrugated solid hand wheel with a soft cloth.

Apply a small amount of lubricant to any moving parts.

Avoid harsh chemicals or abrasive cleaners to protect the surface.

Regular maintenance keeps your bakelite corrugated solid hand wheel working smoothly. The corrosion-resistant materials and strong construction help it last for years. When you follow the bakelite handwheels specifications, you ensure both safety and performance.

Note: Proper assembly and care of your bakelite corrugated solid hand wheel help you get the most out of your equipment.

When you choose a cast iron handwheel, you often see two main shapes: flat and dished. Each shape has its own features and benefits. Understanding these differences helps you pick the right one for your machine.

Flat handwheels have a solid, flat structure. The wheel and hub sit on the same plane. You can use them as knobs or cranks, not just as wheels.

The closed rim on a flat handwheel blocks access to the shaft. This design helps prevent injuries by keeping your hands away from moving parts.

Flat handwheels are heavier. They work best for smaller or medium-sized machines, not for very large diameters.

Dished handwheels have an offset outer rim. This means the rim sits at an angle or is set away from the hub.

You can find dished handwheels in both spoked and solid designs. The offset shape often feels more comfortable in your hand.

Dished handwheels may improve ergonomics. The angle can make it easier to grip and turn, especially during long shifts.

You should think about how you will use the handwheel. If you want extra safety and a solid feel, a flat handwheel is a good choice. If you need better comfort or a larger size, a dished handwheel may suit your needs.

You can select a cast iron handwheel with a handle or without one. The handle changes how you use the wheel and how much control you have.

A handwheel with a handle gives you a better grip. You can turn the wheel more easily, especially when you need to apply more force.

Handles help reduce hand fatigue. You do not have to squeeze the rim as tightly.

Some handles revolve, spinning freely as you turn the wheel. This feature makes long or repetitive tasks easier.

A handwheel without a handle offers a smooth, simple look. You may prefer this style for machines that need only small adjustments.

Foshan Grace Machinery Co., Ltd. offers both options. You can choose the style that fits your machine and your comfort.

Tip: If you use the handwheel often or for heavy tasks, pick one with a handle for better control and less strain.

You want your handwheel to last a long time. Cast iron stands out for its durability. This material resists wear and tear, even in tough industrial settings.

Cast iron does not bend or break easily. You can trust it for heavy-duty jobs.

The solid structure holds up under high force. You can use it on presses, lathes, and other demanding machines.

Cast iron resists damage from oils, grease, and many chemicals. This makes it a smart choice for factories and workshops.

The weight of cast iron adds stability. Your handwheel will not slip or wobble during use.

Foshan Grace Machinery Co., Ltd. uses high-quality cast iron for their handwheels. Their products meet strict standards for strength and reliability. You can count on them for years of safe, smooth operation.

Note: Regular cleaning and inspection help maintain the durability of your cast iron handwheel. Check for cracks or signs of wear to keep your equipment running safely.

When you select a handwheel, you should first think about how you will use it. Different machines require different types of adjustments. For example, you might need a handwheel for valve control, machinery adjustment, or fine-tuning a setting. The size and style of the handwheel matter. Small handwheels work well for light-duty tasks, while large ones give you more leverage for heavy-duty jobs.

Here is a table to help you compare important criteria:

| Criteria Category | Considerations |

|---|---|

| Function | Type of adjustment (valve, machinery, fine-tuning) |

| Size | Diameter based on required force (small for light, large for heavy) |

| Material | Strength, durability, corrosion resistance, weight |

| Style | Spoked (lighter, high torque), solid (safety), dished, safety clutch |

| Handle Options | With or without handle, fold-away, revolving, finger grip |

| Hub Styles | Mounting method (square, hex, screw set) |

| Bore and Keyway Prep | Bore types and keyways for locking and torque transmission |

| Ergonomics & Safety | Operator comfort, safety hazards, operational environment |

| Industry Standards | ANSI, OSHA, and other safety and sizing standards |

You should match the handwheel to your machine’s needs. If you need high torque, choose a spoked or large-diameter handwheel. For safety, a solid or flat handwheel works best. Always check if your application requires special features, such as a fold-away handle or a specific mounting hub.

The environment where you use your handwheel affects your choice of material. Temperature, humidity, and chemical exposure can change how a handwheel performs. For example, cast iron handwheels work well in high temperatures but may rust in humid areas. Plastic handwheels resist rust but may soften in heat. Aluminum handwheels offer a good balance for outdoor or moist environments.

| Material Type | Temperature Range (°C) | Environmental Considerations |

|---|---|---|

| Cast Iron Handwheels | -20 to 300 | Durable, but moisture can cause corrosion |

| Plastic Hollow Handwheels | -10 to 80 | Good for dry, mild settings; must resist chemicals and moisture |

| Aluminum Hollow Handwheels | Up to 200 | Resists rust, handles moderate heat, needs chemical resistance |

| Steel Machine Tool Handwheels | -40 to 400 | Wide range, but needs corrosion protection in humid/chemical areas |

Tip: Always consider the working environment before choosing a handwheel. This helps you avoid problems with rust, heat, or chemical damage. If you need alternatives to bakelite handwheels, look at aluminum or steel for better performance in extreme conditions.

Ergonomics play a big role in operator comfort and safety. You want a handwheel that feels good in your hand and reduces fatigue. Look for these ergonomic features:

Contoured grips that fit your hand and spread out the force.

Balanced size and weight for easy, precise turning.

Smooth surfaces and well-balanced weight for better control.

Clear, visible scales for accurate adjustments.

Handles designed for use with gloves or bare hands.

Foldaway handles help prevent accidental bumps.

Finger grip edges give you more control and reduce slipping.

Durable materials add to both comfort and safety.

Note: Good ergonomics help you work longer without strain and lower your risk of injury. Always test the grip and feel before making your final choice.

When you choose a handwheel for your machinery, your budget plays a big role. Prices can vary a lot, depending on the type, material, and brand you select. You want to get the best value for your money, but you also need a product that meets your needs for strength, durability, and comfort.

You will notice that handwheels made from high-quality materials like stainless steel or carbon steel usually cost more. These materials last longer and handle tough jobs, so you pay for better performance. Plastic handwheels cost less and work well for light-duty tasks. If you only need a simple solution, plastic is a good choice. For heavy-duty or precise work, you may want to invest in a stronger material.

Brand reputation also affects price. Well-known brands often charge more because they use advanced manufacturing and strict quality control. Newer or local brands may offer lower prices, but you should check their quality before buying. Custom features, such as ergonomic handles or special coatings, can also raise the price.

Here is a table that compares the costs of different handwheel types and materials:

| Handwheel Type | Brand Type | Material | Price (USD) | Influencing Factors |

|---|---|---|---|---|

| Ball Valve Handwheel | Established Intl. Brand | High-quality Carbon Steel | $50 | Precision machining, durability |

| Ball Valve Handwheel | Local Brand | Lower-grade Carbon Steel | $30 | Basic manufacturing, lower material grade |

| Lathe Round Spoked Handwheel | Reputable Brand | Stainless Steel | $80 | Complex machining, corrosion resistance |

| Lathe Round Spoked Handwheel | New Market Entrant | Carbon Steel | $40 | Simpler design, less precise manufacturing |

| Plastic Handwheel (Light-duty) | Cost-effective Brand | Plastic | $15 | Simple design, light-duty application |

| Heavy-duty Handwheel | Premium Brand | Carbon Steel + High-strength Plastics | $60 | Advanced ergonomic design, heavy-duty use |

You can see that prices range from $15 for a basic plastic handwheel to $80 for a premium stainless steel model. The main factors that influence cost include:

Material quality: Stainless steel and carbon steel cost more than plastic.

Manufacturing complexity: Precision machining and advanced designs increase the price.

Brand reputation: Well-known brands often charge more for their products.

Customization: Special features or custom sizes add to the cost.

Tip: Set your budget based on your application. If you need a handwheel for heavy-duty or frequent use, consider spending more for better quality. For simple or occasional tasks, a cost-effective option may be enough.

You should always balance cost with performance. A low-priced handwheel may save you money now, but a high-quality product can last longer and reduce downtime. Think about your needs, compare options, and choose the best value for your budget.

Proper maintenance keeps your handwheel working smoothly and safely. You can extend its lifespan and reduce the risk of breakdowns by following a few simple steps. This section explains the cleaning, inspection, and replacement process for your handwheel.

You should clean your handwheel regularly to prevent dirt and debris from building up. Use a soft cloth to wipe the surface. For stubborn grime, use mild soap and water. Avoid harsh chemicals that might damage the material. If your handwheel has moving parts, such as a revolving handle, apply a small amount of manufacturer-recommended lubricant. This reduces friction and helps the handle turn easily.

Remove dust and grease after each use.

Clean the area around the handwheel to keep the machine safe.

Dry the handwheel completely before using it again.

Tip: Clean handwheels not only look better but also work better. Regular cleaning prevents corrosion and keeps your equipment in top shape.

Regular inspection is a key part of maintenance and care requirements. You should check your handwheel for signs of wear, cracks, or corrosion. Look at the mounting area to make sure the handwheel stays secure. If you notice any loose parts, tighten them right away.

Follow these best practices for inspection:

Examine the handwheel and nearby components for damage or leaks.

Test the handwheel by turning it gently. Listen for unusual noises or feel for rough spots.

Check for rust or corrosion, especially if you use the machine in a humid or chemical-rich environment.

Lubricate moving parts as needed to keep everything running smoothly.

Keep a record of your inspections and any repairs you make.

Note: Early detection of problems helps you avoid costly repairs and keeps your machine safe to use.

Sometimes, cleaning and inspection are not enough. If you find deep cracks, severe corrosion, or broken handles, you should replace the handwheel. Using a damaged handwheel can lead to accidents or machine failure.

Remove the old handwheel carefully, following the manufacturer’s instructions.

Choose a new handwheel that matches your machine’s size and application.

Install the new handwheel securely and test it before returning the machine to service.

You should always operate the handwheel gently and avoid using excessive force. This simple habit extends the life of your equipment and keeps your workplace safe.

Remember: Regular maintenance, careful inspection, and timely replacement help you get the most out of your handwheel.

You have many options when choosing a handwheel. You can select from spoked, solid, or folding designs. Materials include steel, aluminum, and the bakelite corrugated solid hand wheel. The bakelite corrugated solid hand wheel offers comfort, safety, and proven durability. You should always match the bakelite corrugated solid hand wheel to your machine’s needs. The bakelite corrugated solid hand wheel fits many applications. You can trust the bakelite corrugated solid hand wheel for reliable performance. Always check the specifications of the bakelite corrugated solid hand wheel. For expert help, contact Foshan Grace Machinery Co., Ltd. about the bakelite corrugated solid hand wheel.

You use a handwheel to manually control or adjust machine parts. Handwheels give you precise movement and easy operation for tasks like opening valves, setting machine positions, or making fine adjustments.

You should match the handwheel size to your application. Larger handwheels give you more leverage for heavy-duty tasks. Smaller handwheels work best for light adjustments or tight spaces.

Yes, you can use a bakelite handwheel in high temperatures. Bakelite resists heat up to 150°C. This makes it suitable for many industrial machines that operate in warm conditions.

A fixed handwheel rotates with the shaft when you turn it. A revolving handwheel has a handle that spins freely, making it easier for you to turn the wheel during long or repetitive tasks.

You should clean your handwheel regularly with a soft cloth. Inspect it for cracks or wear. Lubricate moving parts if needed. Replace damaged handwheels to keep your machine safe and efficient.

Plastic handwheels work well for light-duty applications. You can use them on small machines or equipment that does not require much force. For heavy-duty tasks, choose metal or bakelite handwheels.

Yes, you can replace a handwheel by following the manufacturer’s instructions. Make sure you select the correct size and type. Secure the new handwheel tightly before using your machine.