close

Choose Your Site

Global

Social Media

A handwheel lets you control and adjust machinery or equipment with accuracy. You often use a handwheel when you need to open or close a valve. In factories, you might find a handwheel attached to a valve that controls the flow of liquids or gases. When you turn the handwheel, the valve moves to allow or stop the flow. You can see handwheels on different types of valves, such as gate valves, globe valves, and ball valves. Each valve needs a handwheel for smooth operation. In oil and gas plants, a handwheel on a valve helps manage pressure and safety. Many industries rely on a handwheel to make quick, precise changes to a valve. You might also use a handwheel for adjusting a valve in water treatment or chemical processing. The handwheel remains a key tool for anyone who needs to control a valve quickly and safely. Every time you use a valve, the handwheel gives you the grip and control needed for the task.

A handwheel lets you control valves and machinery by turning it with your hand, giving you precise and safe adjustments.

Different handwheel types—solid, spoked, and folding—offer unique benefits like safety, ease of use, and space-saving features.

Choosing the right handwheel material and size improves durability, comfort, and control for your specific valve and environment.

Handwheels provide direct feedback during valve operation, helping you avoid damage and maintain safety in many industries.

Proper selection and installation of handwheels ensure smooth, reliable valve control and reduce fatigue during long use.

You use a handwheel as a control component that lets you adjust or clamp machinery by turning it with your hand. In mechanical engineering, a handwheel mechanism is defined by several standards that ensure safety, comfort, and efficiency.

A handwheel consists of a wheel that you operate by hand, designed for precise adjustment and clamping through a rotating action.

Standards such as MIL H-9859, GOST, MSS SP-91-2009, ANSI, HFES, and OSHA set the technical and ergonomic requirements for handwheels.

These standards help you choose the right handwheel for manual operation, especially when you need to control a valve or other manually operated device.

You often see a handwheel mechanism on valves in industrial settings, where it provides reliable manual control.

When you turn a handwheel, you use the principle of mechanical advantage. The handwheel mechanism works like a rotary lever. You apply force at the rim, and this force creates torque around the center. This action allows you to move or adjust a valve with less effort. The handwheel revolves around an axis, which means your hand movement turns the wheel and transmits motion to the connected shaft or valve stem.

Tip: A larger handwheel diameter gives you more control and makes manual handwheel operation easier, especially when you need to make small, precise adjustments.

Here is how the handwheel mechanism helps you in manual operation:

The handwheel acts as a rotary lever. The diameter of the wheel increases the lever arm, so you get more torque for the same amount of force.

A larger handwheel lets you make smaller, more accurate movements. This is important when you need to adjust a valve with precision.

The size of the handwheel affects ergonomics. If the wheel is too small, you need more force, which can cause fatigue. If it is too large, it may feel awkward. A medium or large handwheel balances comfort and control.

Smaller handwheels allow you to move tools or valves quickly but with less accuracy. Larger handwheels favor accuracy over speed, so you can choose based on your needs.

You use the handwheel mechanism in many types of valve control. Manual operation of a valve with a handwheel gives you direct feedback and lets you feel the resistance as you open or close the valve. This feedback helps you avoid over-tightening or damaging the valve. In manual handwheel operation, you control the flow of liquids or gases by turning the wheel, making it a vital part of many industrial systems.

When you choose a handwheel for a valve, you need to know the main types available. Each type offers unique features that help you control machinery and valves safely and efficiently. You often see three main types: solid handwheels, spoked handwheels, and folding handwheels. Let’s look at each type and how they work in different valve applications.

A solid handwheel gives you a closed, disk-like structure. You often use this type when you need extra safety around a valve. The solid rim prevents your hand from slipping through, which helps protect you from injury. You find solid handwheels in heavy-duty machinery, presses, and especially on valves that require secure manual control. When you operate a valve with a solid handwheel fitted, you get a firm grip and steady movement.

Solid handwheels are heavier than other types. This weight helps you apply more torque when you need to open or close a valve that is hard to turn. You also see solid handwheels with keyways, which lock the handwheel to the valve stem for precise control. Some models include safety bushings that disengage if you hit the handwheel by accident, keeping you safe.

Foshan Grace Machinery Co., Ltd. offers cast iron solvent-resistant handwheels that work well in tough environments. These handwheels resist chemicals and last a long time, even when you use them on valves in chemical plants or water treatment facilities. You can also find plastic solid handwheels that are lightweight and easy to install, making them perfect for milling machines and valves that need quick adjustments.

Note: Solid handwheels are ideal when you want to prevent axial access and need a strong, reliable grip on a valve.

A spoked handwheel uses open spokes, usually two or three, to connect the rim to the center. This design makes the handwheel lighter and easier to turn, especially when you need to adjust a valve quickly. You often see spoked handwheels fitted to valves in large machinery, mining equipment, and industrial plants.

Spoked handwheels give you better hand positioning. The open spaces let you grip the wheel from different angles, which reduces fatigue during long shifts. You also get improved visibility, so you can see the valve position and spot any issues right away. Many spoked handwheels come with revolving handles. These handles spin as you turn the wheel, making it easier to operate a valve without straining your wrist.

Foshan Grace Machinery Co., Ltd. produces Bakelite three-spoked handwheels with handles. These handwheels are durable and resist corrosion, so you can use them on valves in harsh environments. The keyway feature ensures the handwheel stays locked to the valve stem, giving you precise control over the valve’s movement.

Here is a quick comparison of solid and spoked handwheels:

| Handwheel Type | Key Features | Advantages | Safety Considerations |

|---|---|---|---|

| Solid Handwheel | Closed rim, solid structure, heavier | Prevents axial access, safer for critical valve applications | Heavier, less suitable for large or lightweight needs |

| Spoked Handwheel | Open spokes (2-3), lighter | High-torque, lighter, better grip and control | Open spokes may create pinch points |

Tip: Choose a spoked handwheel fitted to a valve when you want a lighter feel and need to make frequent adjustments.

A folding handwheel stands out because of its fold-away handle. You use this type when you need to save space or reduce the risk of bumping into the handle. The handle folds flat against the wheel when not in use, which helps prevent accidents in tight spaces. When you need to operate the valve, you simply unfold the handle and turn the handwheel.

Folding handwheels are perfect for valves in crowded work areas or on portable machines. The fold-away handle also makes storage easier and protects the handle from damage. Some folding handwheels fitted to valves include automatic folding handles, which snap back into place after use. This feature improves safety and keeps your workspace organized.

Foshan Grace Machinery Co., Ltd. offers folding handwheels designed for easy installation and durability. You can find these handwheels fitted to valves on milling machines, table saws, and other equipment where space is limited. The ergonomic design reduces fatigue, even when you need to adjust the valve many times during a shift.

Folding handwheels fitted to a valve help you avoid accidental contact and keep your work area safe.

You can choose from a wide range of handwheels fitted to valves, each with unique features:

Bakelite three-spoked handwheels with handles for strong grip and corrosion resistance.

Cast iron solvent-resistant handwheels for valves exposed to chemicals.

Plastic handwheels for lightweight, easy-to-install solutions.

Handwheels with keyways for secure attachment to the valve stem.

Handwheels with revolving or fold-away handles for ergonomic operation.

When you select a handwheel fitted to a valve, consider the handwheel height and the handwheel angle. The right handwheel height lets you operate the valve comfortably, while the correct handwheel angle ensures smooth movement and reduces strain. Foshan Grace Machinery Co., Ltd. provides options to match your specific needs, whether you need a handwheel fitted for a horizontal valve or one that works at a 45-degree handwheel angle.

Remember: The right handwheel fitted to your valve improves safety, comfort, and efficiency in every application.

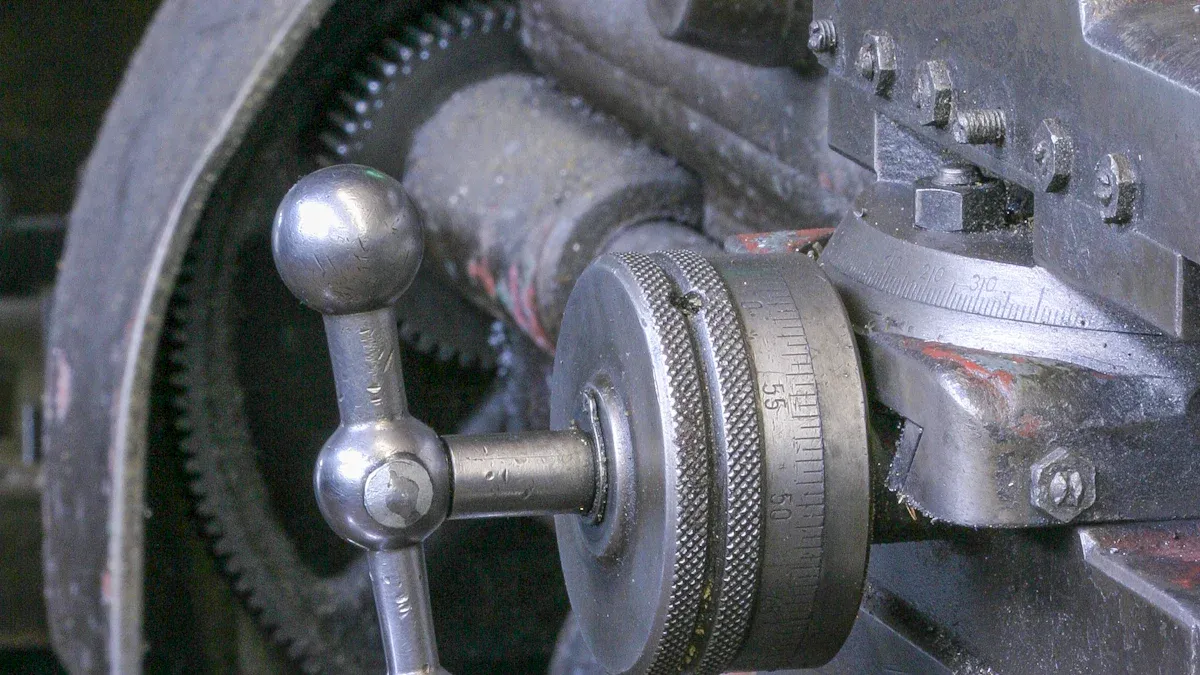

You will find handwheels in many types of industrial machinery. When you work with milling machines or lathes, you often use a handwheel mechanism for precise adjustments. This manual control lets you set the position of a workpiece or tool with accuracy. In manufacturing, you rely on handwheel operation for tasks that need careful movement, such as aligning parts or tightening clamps.

Handwheels also play a key role in automotive manufacturing. You use them to operate machinery that shapes or assembles car parts. In chemical processing plants, you depend on handwheel operation to adjust valves that control the flow of chemicals. Food processing and pharmaceutical industries use handwheels because they offer reliable manual operation and meet strict hygiene standards.

Here is a quick look at where you might use handwheels:

| Application / Industry | Role of Handwheels |

|---|---|

| Industrial Machinery | Control and adjust machine parts |

| Automotive Manufacturing | Operate assembly and testing equipment |

| Chemical Processing | Adjust valves and regulate chemical flow |

| Food & Pharmaceuticals | Ensure hygiene and precise control |

| Oil & Gas | Manage valve operation in pipelines |

You will also see handwheels on table saws and grinder machines. These tools require you to make small, controlled movements, and the handwheel mechanism gives you the grip and feedback you need.

When you need to control a valve, you often turn to a handwheel. The handwheel mechanism connects to the valve stem, letting you raise or lower the gate inside the valve body. This manual operation gives you direct control over the flow of liquids or gases. In oil and gas plants, you use handwheels for valve operation in pipelines, ensuring safe and accurate fluid management.

Manual control is especially important in remote or hazardous locations. Automated systems may not always work, but you can rely on a handwheel for dependable valve operation. Water treatment plants also use handwheels to manage water flow and maintain safety standards. The design of the handwheel mechanism allows you to open or close a valve with minimal effort, providing a tight seal and reducing the risk of leaks.

Tip: Always check that the handwheel fits the valve and matches your operating machinery for smooth manual operation.

When you select a handwheel for a valve, you need to consider several design features. The right handwheel design improves safety, comfort, and control. You can choose from different handle types, shapes, and sizes to match your application.

Handle Types:

With handle: Use this for higher torque when you need to open or close a valve that is hard to turn. Handles can be metal or plastic, and some revolve for easier operation.

Without handle: This style works well for steering wheel-like motion, giving you smooth control over the valve.

Foldaway handles: These fold into the handwheel body, reducing safety risks in tight spaces.

Revolving handles: Best for small handwheels with low torque, making valve adjustments easier.

Finger grip: Grooved edges give you extra control, especially when you need to adjust a valve quickly.

Shapes:

Spoked: Lighter and good for high torque, but open spokes may create pinch points.

Flat (solid/disk): Heavier and safer, preventing your hand from slipping through during valve operation.

Dished: The outer diameter is offset for function or looks.

Safety clutch: Prevents the handwheel from rotating unintentionally, protecting you during machine operation.

Sizes:

Small diameter: Use these for low-force, finger-controlled valve adjustments.

Large diameter: Choose these for high-force applications, such as large industrial valves.

You also need to think about hub styles and bore types. Options include square, hex, half-circle, and screw set hubs. These styles help you attach the handwheel securely to the valve stem. The right handwheel height and handwheel angle make operation more comfortable and reduce fatigue.

Tip: Ergonomic grips and foldaway handles help prevent injuries and make long shifts at the valve safer.

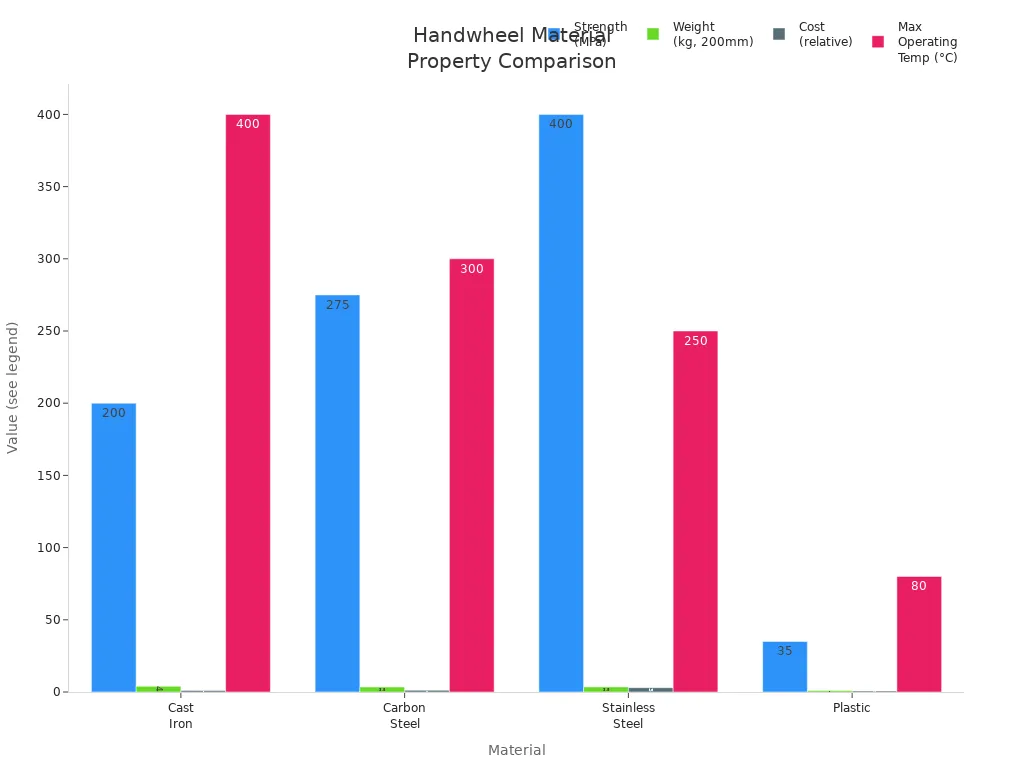

The material you choose for your handwheel affects its strength, durability, and resistance to chemicals. Each material offers unique benefits for different valve applications.

| Material | Strength | Corrosion Resistance | Weight | Cost | Max Temp | Best Use Cases |

|---|---|---|---|---|---|---|

| Cast Iron | Medium | Low | Moderate | Low | High | High-temp, less corrosive valve environments |

| Carbon Steel | Medium-High | Moderate | Moderate | Moderate | High | Building water, HVAC, industrial valves |

| Stainless Steel | High | High | Moderate | High | Moderate | Food, chemical, marine, and medical valves |

| Plastic | Low | Moderate-High | Low | Low | Low | Lightweight, indoor, or aesthetic valve uses |

| Bakelite | High | High | Moderate | Moderate | High | Heavy machinery, CNC, solvent-resistant valves |

You can see how these materials compare in strength, weight, cost, and temperature resistance:

Bakelite stands out for its durability and resistance to solvents, oils, and grease. You can use Bakelite handwheels on a valve in harsh environments, knowing they will last and maintain safety. Plastic handwheels, such as those made from polypropylene or nylon, offer lightweight and corrosion-resistant options for valves that do not require high strength. Cast iron and stainless steel provide the toughness needed for industrial valve applications, especially where high temperatures or chemicals are present.

Foshan Grace Machinery Co., Ltd. focuses on producing handwheels that are easy to install, durable, and resistant to solvents. You can find options that match your required handwheel height and handwheel angle, ensuring the best fit for your valve and machinery.

Selecting the right handwheel fitted to a valve is important for safe and efficient operation. You should consider several factors before making your choice:

Material: Choose from aluminum, plastic, duroplastic, stainless steel, or cast iron. Each material works best in different environments. For example, stainless steel resists corrosion, while cast iron offers strength for heavy-duty valve use.

Size and Style: Pick a handwheel fitted with the right diameter and spoke configuration. A three-spoke or solid disc design can help you control a valve with precision.

Function and Environment: Think about what you need to operate. If you need to adjust machinery or control a valve in a chemical plant, select a handwheel fitted to resist chemicals and heat.

Mounting and Hub Style: Make sure the handwheel fits the valve stem. Check bore size, keyways, and set screws for a secure fit.

Handle Options: Some handwheels have crank or revolving handles. These features help you turn a valve with less effort.

Ergonomics and Safety: Look for designs that protect your hands and reduce fatigue. Safety features are important, especially when you use a handwheel fitted to a valve in hazardous areas.

Industry Standards: Follow standards like ANSI, MIL H-9859, GOST, MSS SP-91-2009, and OSHA. These ensure your handwheel meets safety and sizing rules.

Durability: Pick materials that last and resist corrosion, especially if you use the handwheel on a valve exposed to harsh conditions.

Force Needed: Heavy-duty valves may need a stronger handwheel for proper operation.

Compatibility: Always check that the handwheel matches the valve shaft for smooth operation.

Foshan Grace Machinery offers a wide variety of handwheels for different valve applications. Their customer support team can help you choose the best handwheel fitted for your needs.

Proper installation ensures your handwheel fitted to a valve works safely and reliably. You should follow these steps:

Find the best location for the handwheel on the valve. Align it with the shaft or bore.

Attach the handwheel using the correct fasteners, such as set screws or locking bolts.

Test the handwheel’s motion. Make sure it turns smoothly and adjusts the valve as needed.

You can use different hub styles and bore designs, such as square, hex, or screw set hubs. Keyways and broaching help secure the handwheel to the valve shaft. These methods prevent slippage and keep the handwheel fitted in place during operation.

| Standard / Organization | Application | Description |

|---|---|---|

| ANSI | United States | Safety and manual control standards for handwheels and valves |

| MIL H-9859 | Military | Specs for commercial handwheels 3 inches or larger |

| GOST | Euro-Asian | Technical and ergonomic standards for handwheels |

| MSS SP-91-2009 | United States | Guidelines for manual valve operation and handwheel sizing |

| OSHA | United States | Safety rules for machine and valve operation |

Tip: Never use tools or wrenches to turn a handwheel fitted to a valve. Only use your hand to avoid damage and ensure safety.

Foshan Grace Machinery provides easy-to-install handwheels and technical support. You can reach their team by phone, email, WhatsApp, or Skype for help with selection and installation.

You play a key role in ensuring machinery runs smoothly by selecting the right handwheel for each valve. The correct choice improves precision, safety, and comfort during valve operation. Consider these benefits:

Ergonomic handwheels reduce fatigue and make valve adjustments easier.

Durable materials like plastic or steel lower maintenance costs for each valve.

Proper sizing and design help you control every valve with accuracy.

| Machine Type | Handwheel Type | Valve Application | Performance Impact |

|---|---|---|---|

| Labeling | Stamping | Light-duty valve | Reliable, low wear |

| Carton Sealer | Forged | Heavy-duty valve | High reliability |

Supplier expertise matters when you need a handwheel for a specific valve. Foshan Grace Machinery offers support and a wide range of options for any valve requirement. Reach out to their team for reliable valve solutions.

You use a handwheel to manually open or close a valve. This control lets you adjust the flow of liquids or gases. The handwheel gives you direct feedback, so you can operate the valve safely and precisely.

You should match the handwheel size and material to the valve type and environment. Consider the force needed to turn the valve. Check if the handwheel fits the valve stem securely. Always follow industry standards for safety.

No, you cannot use the same handwheel for every valve. Each valve may need a different handwheel size, shape, or material. You must select a handwheel that matches the valve’s requirements for safe and efficient operation.

Some valves use folding handwheels to save space and prevent accidental bumps. You can fold the handle away when not in use. This design keeps the valve area safer and makes storage easier.

You can choose from cast iron, Bakelite, plastic, or stainless steel. Each material offers benefits for different valve applications. For example, Bakelite resists solvents, while stainless steel works well for valves in corrosive environments.

Tip: Always inspect the handwheel and valve before use to ensure safe operation.